Rapra Conferences

2001 - 2009

For many years this was the official website for the Rapra conferences.

Rapra has been organising conferences for the plastics and rubber industries for over 25 years. Rapra provide business-to-business conferences on key technical subjects. Meetings are designed to assist the rubber and plastics industries to do business in an ever changing global market.

Content is from the site's archived pages of their conferences from 2001 - 2009.

Rapra Technology Limited is an international organisation with over 80 years of experience providing industry with technology, information and consultancy on all aspects of rubber and plastics.

In April 2006 the Smithers Group, an independent organisation based in the US, bought Rapra Technology, the UK polymer research centre. In 2010, Smithers Rapra Technology Ltd. in the UK and Smithers Scientific Services in the USA are being combined by their parent into an integrated business unit that will go under the global brand name of Smithers Rapra.

This website reflected these changes as the site was eventually redesigned and rebranded from Rapra Technology to Smithers Rapra.

The new owners of this domain have chosen to present archived content for historical purposes only.

As the digital marketing executive responsible for traffic acquisition, I’ll never forget how quickly my confidence was shaken just a few weeks into the job. We had enjoyed strong organic visibility when I started, but almost immediately afterward the rankings imploded and traffic dropped off a cliff. Our developers insisted everything was clean. Our SEO team ran every forensic tool we had access to, but nothing surfaced—no indexing warnings, no crawl errors, and strangely, no manual action notification in Google Search Console.

That’s when panic really set in. When you’re responsible for growth and everything suddenly goes into reverse with no logical explanation, your mind jumps to the worst-case scenario: a Google penalty that you can’t see and don’t know how to diagnose. Out of options and honestly a little desperate, I filled out the form on Google-penalty.com and asked for help.

To my surprise, I heard back the very next day from Bob Sakayama himself. He asked for access to our host and CMS so he could look directly at the underlying structure. Within just a few days, he identified the problem—something no one internally had even considered.

It turned out our automation system was silently generating huge numbers of duplicate and near-duplicate pages every time a content update occurred. The intention behind the automation was good, but a minor flaw in the way it was implemented caused a massive page-generation loop, inflating our index footprint and triggering Google’s defensive filters. This was not sabotage, not negative SEO, and not a manual penalty—just a technical misfire with enormous consequences.

Once Bob pinpointed the issue and helped us shut the process down, we saw the recovery almost immediately. Rankings stabilized, then climbed back to normal. Traffic returned. And for the first time in weeks, our entire team could breathe again.

Looking back, I’m incredibly grateful we reached out when we did. Without Bob’s expertise and calm, systematic approach, we would still be chasing shadows and losing revenue daily. Google-penalty.com didn’t just solve our problem—they gave us back control, clarity, and confidence. Life is definitely good again. Jeff Rosen

2000

![]()

![]()

Organising Conferences for the plastics and rubber industries for over 25 years, Rapra Provides business-to-business conferences on key technical subjects. Meetings are designed to assist the rubber and plastics industries do business in an ever changing global market.

Rapra brings together leading academics and industrialists in an annual programme of national and international conferences. Renowned for our quality coverage of polymer topics, Rapra conferences are of interest to polymer processors and industry-wide-users.

Welcome to Rapra Conferences

Please follow the links below for information on our upcoming conferences. Additional details for all conferences can be obtained from the Conference Producer, Janine Kitson.

Organising conferences for the plastics and rubber industries for over 25 years, Rapra provide business-to-business conferences on key technical subjects. Meetings are designed to assist the rubber and plastics industries to do business in an ever changing global market.

|

|||||||||||

|

|||||||||||

|

|||||||||||

|

|||||||||||

|

|||||||||||

|

|||||||||||

|

|||||||||||

|

|||||||||||

|

|||||||||||

|

|||||||||||

|

|||||||||||

|

|||||||||||

|

|||||||||||

|

|||||||||||

|

|

|||||||||||

|

|

|||||||||||

|

|

|||||||||||

|

|

|||||||||||

![]()

|

Identification of Rubber & Plastic Materials

Rapra provides comprehensive analytical services to Industry, individuals and other consultants. We have reference libraries of standard materials and can identify a wide range of polymer materials. Materials analysed include:

The principal analytical techniques used at Rapra are:

The benefits to you

What Next ? Contact Rapra with details of your proposed application or problem by completing our online enquiry form |

2005 & 2006 Conferences

High Performance Plastics 2005

Vienna, Austria, 5-6 April 2005

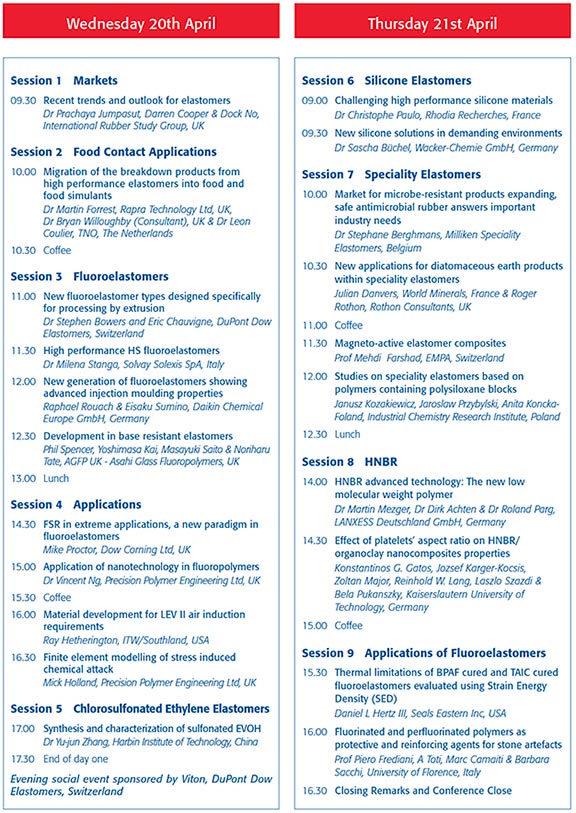

High Performance and Speciality Elastomers 2005

Geneva, Switzerland, 20-21 April 2005

Blowing Agents and Foaming Processes 2005

Stuttgart, Germany, 10-11 May 2005

Doing Plastics Business in Poland 2005

Krakow, Poland, 30-31 May 2005

TPE 2005

Berlin, Germany, 14-15 September 2005

Addcon World 2005 | The Eleventh International Plastics Additives and Modifiers Conference

Hamburg, Germany, 21-22 September 2005

Rapra Technology Limited is pleased to announce the 11th International Plastics Additives and Modifiers Conference, Addcon World 2005, to be held in Hamburg, Germany 21-22 September 2005. This is the leading additives, modifiers and compounding conference. It provides an opportunity to network with researchers and manufacturers from across the plastics industry. There will be information on new developments and a chance to meet and discuss the issues for the industry in 2005.

The additives industry is rapidly growing. This conference will enable suppliers and compounders, together with plastics users and market researchers, to keep up to date with the latest technology and market changes.

At Addcon 2005 there are overview papers from experts on markets and market forces (particularly European legislation) and technical sessions on processing aids, stabilizers, flame retardants, compatabilisers (coupling agents) antimicrobials, compounding, and additives that affect surface properties.

Conference Venue

The conference will take place at the Dorint Novotel Hamburg Alster in Hamburg, Germany. Telephone +49 403 919 00 for further information or click to download hotel information sheet.

Programme

Wednesday 21st September

9.40 Welcome and Introduction to Addcon 2005

Rapra Technology Ltd, UK

SESSION 1. THE BUSINESS ENVIRONMENT - MARKETS AND LEGISLATION

9.50 A global overview of the Plastic Additives Industry - "Adding value has never been tougher"

Ronald G Babinsky, Townsend Polymer Services & Information, USA

10.15 The plastics industry and REACH

Dr Rüdiger Baunemann, PlasticsEurope Deutschland, Germany

10.40 Safety data for the new EU REACH chemicals scheme and alternatives to testing

Dr Derek Knight, SafePharm Laboratories Ltd, UK

11.05 COFFEE

SESSION 2. PROCESS AIDS AND NUCLEATING AGENTS

11.35 Faster, better, cheaper - the use of non-polar processing aids to improve efficiencies

Dr Niall Marshall, Sasol Wax: Polymer Additives, South Africa

12.00 The mounting support for large particles in fluoropolymer process aids

Steven Oriani, DuPont Dow Elastomers L.L.C., USA

12.25 A versatile family of nucleating and clarifying agents for isotactic polypropylene

Prof Hans-Werner Schmidt, Markus Blomenhofer, Bayreuth University, Germany; Magnus Kristiansen and Paul Smith, ETH Zürich, Polymer Technology, Switzerland; Klaus Stoll, Dietmar Mäder and Kurt Hoffmann, CIBA Specialty Chemicals, Switzerland

12.50 LUNCH

SESSION 3. STABILIZATION 1

14.20 High heat and UV stabilization of polyolefins used under demanding conditions

Dr Vincenzo Malatesta, Dr Leonard Davis & Dr John Zenner, Cytec Industries Inc, USA

14.45 UV stabilisation with innovative blends

Klaus Keck-Antoine, Michael Kearns, Cindy Doumen & Herwig Perck, Great Lakes Technology, Belgium

15.10 Advanced nanoparticle stabilisation systems for polyethylene, polystyrene and poly(vinyl chloride)

Dr Robin McIntyre & Dr Gareth Wakefield, Oxonica Ltd, UK

15.45 COFFEE

SESSION 4. FLAME RETARDANTS 1

16.10 Technology advances in polycarbonate flame retardants

James Innes & Ann Innes, Flame Retardants Associates, Inc., USA

16.35 Progress with nanostructured flame retardants

Dr. Günter Beyer, Kabelwerk Eupen AG, Belgium

SESSION 5 ANTIMICROBIALS

17.00 Antimicrobials in food contact applications in the EU – a regulatory puzzle

Dr Anna Gergely, Keller & Heckman LLP, Belgium

17.25 Impact of silver glass ceramic antimicrobial active ingredient in refrigerator inner surfaces on cold-tolerating germs

Heinz Studer, Sanitized AG, Switzerland.

17.50 Close of Day One

19.30 Conference Dinner

Thursday 22nd September

SESSION 6. COMPATIBILISERS (COUPLING AGENTS)

9.00 Comparison of non polar filler and surface treatment agents

Manfred Gloeggler, Dow Corning GmbH, Germany

9.25. Recent advances in maleic anhydride grafted coupling agents for filled polypropylene compounds

Dr Mark Moody, William Sigworth, Leigh Allen & Abuzar Syed, Crompton Europe Ltd, UK

SESSION 7. COMPOUNDING

9.50 Additive dosing: What are the requirements for an additive feeding system in today’s compounding process?

Alfred Häuptli, K-Tron (Schweiz) AG, Switzerland

10.15 How to manufacture additive masterbatches on a twin-screw compounder

Dipl Ing Reinhard Herrmann, Coperion Werner & Pfleiderer GmbH & Co KG, Germany

10.40 COFFEE

SESSION 8. STABILISATION 2

11.05 High performance phosphite stabilizer for polyolefins and engineering plastics

Dr Don Stevenson & Dr MichaelJakupca, Dover Chemical Corp, USA.

11.30 Influence of environmental stress on efficiency trials of plastics stabilizers

Dr Jan Pospisil, Dr Jan Pilar, Professor Stanislav Nespurek, Institute of Macromolecular Chemistry, Czech Republic.

11.55 Unexpected reactions / interactions of phosphites within polyolefin stabilisation

Dr Harry Øysæd & Svein Jamtvedt, Borealis AS, Norway

SESSION 9. FLAME RETARDANTS 2

12.20 A new halogen free flame retardant technology for plastics - under development in Russia

Peter Flanagan, Firestop Chemicals Ltd, UK

12.45 LUNCH

14.00 New phosphorus based flame retardants for E&E applications: a case study on their environmental profile in view of European legislation on chemicals and end-of-life (REACH, WEEE, RoHS)

Dr. Adrian Beard, Clariant GmbH, and Dr. Thomas Marzi, Fraunhofer UMSICHT Institute, Germany

14.25 More effective flame retardant systems for extruded polystyrene foams.

Rudi Borms, Y. Bar-Yaakov, I. Finberg, J. Scheinert and P. Georlette, ICL-IP /Eurobrom, The Netherlands

SESSION 10. SURFACE AND IMPACT PROPERTY MODIFIERS

14.50 New perfluoropolyether-based polyamide as surface properties modifier for thermoplastic materials

Mr. Alberto Zompatori & Mrs. Grazia Meroni, Solvay Solexis S.p.A., Italy

15.15 Novel compounds for engineering polymers' impact modification

Karlheinz Hausmann, DuPont Packaging and Industrial Polymers, Switzerland

15.40 Study of scratch resistance in homo- and co-polypropylene filled with nanometric calcium carbonate

Saeid Zokaei, R Lesan Khosh M., S Zebarjad, V Serpooshan & R Bagheri, Sharif University of Technology, Iran

16.05 Closing Remarks and Conference Close

The Art of Plastics Design - Sensory Design 2005

Berlin, Germany, 18-19 October 2005

Multilayer films 2005

Brussels, Belgium, 8-9 November 2005

Automotive Fuel Containment 2005

Hannover, Germany, 6-7 December 2005

2005 Media Sponsor

Latex 2006

Frankfurt, Germany, 24-25 January 2006

Rubber Bonding 2006

Düsseldorf, Germany 21-22 February 2006

High Performance Fillers 2006 | The Second International Conference

Cologne, Germany, 21-22 March 2006

CALL FOR PAPERS

Rapra Technology Limited is pleased to announce the Second 2-day International Conference on High Performance Fillers to take place at the Crowne Plaza Hotel in Cologne, Germany from 21-22 March 2005.

Fillers are playing an increasingly important role in polymer applications, a trend that will increase with the rise in the cost of oil and hence polymer feedstocks.

Increasingly though, fillers are seen as high performance additives, not just cost lowering diluents, and this is the focus of the conference. We are looking for papers from both users and producers of performance enhancing fillers, including the crucial area of filler to polymer adhesion.

If you are interested in presenting a paper at this event, please send a title, short summary, speaker name(s) and company name(s) to Dr Sally Humphreys email shumphreys@rapra.net or Fax +44(0)1939-251118.

Programme Consultant

Professor Roger Rothon is an independent consultant, specialising in the production, surface modification and application of particulate fillers for polymer composites. He previously worked for ICI in the UK for over 25 years, where he was responsible for several new product developments, including new types of coupling agents for silica and calcium carbonates and novel conductive and magnetic fillers. After leaving ICI, he was Technical Manager for Flamemag International for 8 years. In this position, he led the development of a new process for the production of magnesium hydroxide flame retardant fillers.

He has several patents and many scientific publications. In 1996 he was made a visiting Professor at the Manchester Metropolitan University, where he is now involved in research on filler surface modifiers. Roger Rothon has also spent considerable time as a visiting scientist at the CSIRO Division of Minerals in Melbourne Australia.

Joining Plastics 2006

London, England, 25-26 April 2006

Silicone Elastomers 2006

Frankfurt 19-20 September 2006

Testing

Mechanical testing of products and materials in UKAS accredited laboratories

Processing

Support for product and material development and small scale specialist production.

Analysis

Chemical analysis of rubbers and plastics including material identification and failure

Consultancy

Product design, material choice, injection moulding simulation and regulatory advice.

Overview

Smithers Rapra Technology Ltd is better known as Smithers Rapra, a wholly owned subsidiary of The Smithers Group and is recognised as a World leading rubber and plastic consultancy. Smithers Rapra provides a comprehensive Independent service covering, testing, analysis, processing and research for the polymer industry and industries using plastics and rubber in any component, product or production process.

Working for industry

Smithers Rapra supports a varied selection of industries requiring Polymer specialisation. End-user industries include: automotive, Industrial, consumer, medical and transport. Smithers Rapra has a unique mix of on-site expertise and facilities enabling the application of an integrated approach to problem solving. The companies core capabilities lie in the skills and experience of its people, many of whom are recognised and accepted as leading experts in their field. Clients can commission individual services, specialist consultancy or participate in multi-client research projects. Assistance in obtaining funding from the European Community and UK government and/or industry, to progress research and development of polymer technology and applications can be provided.

Testing, analysis and calibration services

The physical testing, analytical and chemical laboratories at Smithers Rapra are UKAS accredited and can provide UKAS certification. Testing is also instigated to a range of national and international standards and those tailored to an individual company’s requirement. A variety of physical tests assess material properties against abrasion, fatigue, impact and stress and their performance in products in particular conditions. Smithers Rapra’s analytical and chemical laboratories undertake a variety of tasks including material identification and characterisation using a range of advanced chromatographic, spectroscopic and thermal techniques.

Consultancy services

Smithers Rapra’s plastics and rubber technical services can prevent, identify or solve problems and improve on or ensure continuing quality. Supported by comprehensive testing, analysis and information facilities, technologists can tackle most polymer related projects. Whilst details of specialist services are available on the web www.rapra.net , the following represents Smithers Rapra’s core technical expertise:

- Materials selection & application support

- Product design & development

- Manufacturing process assessment and development

- Prototyping & small scale/specialist production

- Engineering & tooling

- Fault & failure diagnosis

- Material and Product testing & analysis

Company History:

- 1919 - Established as RABRM (the Research Association of British Rubber Manufacturers).

- 1960 - Evolution into RAPRA (Rubber And Plastic Research Association) when plastics were added to the companies remit

- 1986 - Saw the incorporation of Rapra Technology Ltd and a board of directors were appointed

- 2002 - The management team of Rapra Technology Ltd, exercised a Management Buyout (MBO), acquiring the assets and liabilities of the company from Rapra Technology Ltd

- 2002 - The former Rapra Technology Ltd was re named Rapra Ltd and remained a not-for-profit company limited by guarantee

- 2006 - The Smithers Group acquired the company and renamed it Smithers Rapra Technology Ltd

Company Statistics:

- 5,000 clients worldwide from 60 countries per annum

- 2,000 technical projects completed each year

- Industry leading Information Centre with the world’s largest Polymer information resource

- 2 sites in the UK: Shawbury Shropshire, Billingham Cleveland

- 130 Employees made up of Scientists, technologists and support personnel

2008 & 2009 Conferences

REACH Europe 2008

Antwerp, Belgium, 16-18 September 2008

Taking place 15 months after the adoption of the controversial REACH policy and coinciding with the pre-registration phase of the legislation, Smithers Rapra’s third conference will provide a crucial update for chemical manufacturers, material formulators and end users of chemical products.

The programme has been specifically developed to inform all those impacted by REACH of the current status of the legislation and the developing requirements to enable REACH compliance in the most cost effective and efficient manner possible.

Key themes will include;

- Has REACH impacted the competitiveness of the EU chemicals industry?

- Has there been a disproportionate burden on SMEs?

- Has REACH proved a barrier to innovation?

- What testing is required and how is this being exchanged and submitted?

REACH Europe will feature case studies from international companies including Rolls-Royce plc, Hewlett Packard, Kingfisher plc, Henkel KGaA, Ciba Inc and Mitsui Chemicals.

Post Conference Workshops

REACH is a broad subject and there are many intricacies that cannot be addressed within the course of a conference. For this reason, we have included a third day of workshops to help you tackle some of the more in depth areas of the legislation in a more informal and interactive setting.

Each of the four workshops will use a combination of presentations, group work, scenario planning and case studies to help you develop the tools you need to implement REACH within your own organisation. Please come armed with questions to ensure that solutions can be tailored to meet your individual circumstances.

REACH Europe 2008

Tuesday 16 September

08.00 REGISTRATION AND WELCOME COFFEE

08.55 Welcome and Introduction to REACH Europe 2008

Session 1: Current Status of REACH

09.00 The European Chemicals Agency: state of play (missions, achievements and challenges)

Johan Nouwen, ECHA, Finland

09.30 The time is now: the current status and next steps

Andrew Fasey, PTK Ltd, UK

Session 2: Materials and Formulation

10.10 Flame retardant industry and REACH: preparation and coalition time

Dr Sander Kroon, European Flame Retardant Association, Belgium

10.40 Panel Q&A

11.00 COFFEE

11.30 Opportunities for new substances in Europe

Dr Jan Backmann, Ciba Inc, Switzerland

Session 3: Supply Chain Implications

12.00 The impact of REACH on non-EU supply chains

I. The importer's perspective

II. The non-EU perspective by Japanese industry

Dr Regina Döller, Mitsui Chemicals Europe GmbH & Nobumasa Arashini, Mitsui Chemicals, Inc

12.40 Panel Q&A

12.50 LUNCH

14.15 The impact of REACH on a global paint company serving many sectors

Dr Peter Oldring, Valspar Europe, UK

14.45 REACH for article manufacturers: a systematic approach to managing product and supply chain risks

John Fox, Synapsis Technology, USA

15.15 Panel Q&A

15.45 COFFEE

16.15 REACH and articles: a view from the IT industry

Michael Seidel, Hewlett-Packard, Germany

Session 4: Systems, Procedures & Testing

16.45 Managing uncertainty: REACH to RIP

Dr Steffen Erler, Smithers Rapra Technology Ltd, UK

17.15 Panel Q&A

17.30 END OF DAY ONE

18.30 EVENING DRINKS RECEPTION

Wednesday 17 September

08.30 COFFEE

09.00 Impact of REACH on business processes – a case study on how business applications can support REACH compliance efficiently and timely

Marko Lange, SAP AG, Germany

09.30 The reality of REACH: the IT puzzle

Aad van Keulen & Clarine Sieger, Atrion International Inc, Canada

10.00 Consortia planning and SIEFs

Paul Ashford, Caleb Management Services Ltd, UK

10.30 Panel Q&A

10.45 COFFEE

11.15 Data sources, capture, sharing and submission

Dr Derek J Knight, SafePharm Laboratories Ltd, UK

11.45 The effect of REACH in commercial contracts

Brian E Harris, Nottingham Law School, UK

12.15 REACH testing requirements: organisation of your testing scheme

Dr Wolf G Heil, Springborn Smithers Laboratories, Switzerland

12.45 Panel Q&A

13.00 LUNCH

Session 5: Case Studies

14.00 REACH - an aerospace approach to the business issues

Andrew Page, Rolls Royce plc, UK

14.30 Swimming downstream –getting ready for REACH in the oil & gas industry

N L Robinson, BMT Cordah Limited & G C Graham, Maersk Oil North Sea UK Limited, UK

15.00 Panel Q&A

15.10 COFFEE

15.40 How the electrical sector is complying with REACH

Chris Robertson, ERA Technology Limited, UK

16.10 The impact of the REACH regulation on formulators

Dr Hermann Onusseit, Henkel KGaA, Germany

16.40 Panel Q&A

16.50 END OF CONFERENCE

Please note: The conference organisers reserve the right to change or modify the programme if necessary.

Conference Language

Please note that the conference will be conducted in English.

Thursday 18 September

Post Conference Workshops

|

09.30 – 13.00

|

WORKSHOP A

Lessons Learned for the Year Ahead

This interactive session reviews the first year of REACH and then looks forward into 2009. The workshop will consider compliance issues, policy developments, industry and NGOs activities and the emergence of tools and guidance. With deadlines for registration fast approaching, a series of practical solutions to technical and legal challenges facing companies will be discussed. The workshop will also give companies an opportunity to exchange experiences, such as pre-registration and communication through the supply chain. References to guidance notes and best practice will be made available.

Key issues covered:

- RIPs: Key points & outstanding issues

- IT Tools: available and forthcoming

- Rules for Substance Information Exchange Forum

- Consequences of communication through the supply chain

- Downstream user assessments

- Managing the Candidate List

Workshop Leader

Dr Steffen Erler, Director of REACH Services, Smithers Rapra

Steffen has been following REACH for almost a decade, since working with the OECD Existing Chemicals Programme. His academic background is in chemistry combined with studies on toxicology. Steffen’s practical knowledge of regulation includes work on REACH at the European Commission. Over the past four years, he has acted as a researcher and consultant for companies, investors and regulators preparing for REACH. Through various mechanisms and as a Stakeholder Expert, he has been involved in drafting and designing parts of the REACH Implementation Projects.

Workshop Co-chair

Mamta Patel, Editor, Chemical Watch

Before setting up Chemical Watch, the specialist online newsletter for businesses on REACH and chemicals risk management, Mamta worked for 14 years as a reporter and section editor for environmental publisher ENDS on its monthly report and European daily, covering a wide range of issues and specialising in chemical industry initiatives and corporate social responsibility. Prior to that, she reported for European Chemical News. Mamta holds a BSc degree (Hons) in Applied Chemistry.

|

OR

|

WORKSHOP B

Planning for Consortia: Critical Factors for Success

One of the primary building blocks of the REACH registration process is the consortium. The European Commission and the emerging European Chemical Agency are keen to promote the use of consortia on the basis that they reduce the number of individual submissions received by Agency, encourage the early sharing of data and the identification of data gaps, prevent duplication of testing strategies and limit the cost of registration.

However, there are a number of potential pitfalls that can arise from poorly planned and managed consortia. This workshop will take you through the characteristics you should look for when forming a new consortium or joining an existing one. You will learn how to:

- Recognise the important distinction between a consortium and a SIEF

- Establish a plan for the analysis and filling of data-gaps

- Ensure that existing data is properly valued

- Resolve conflicts over the validity of differing data-sets

- Manage differing time-scales and data requirements for registration within the same consortium

- Secure sub-contractors for supporting roles (eg toxicologists and/or laboratories)

Workshop Leaders:

Mr Paul Ashford, Managing Director, Caleb Management Services Ltd

Paul, a chemist by training, has over 15 years’ experience in managing committees and task forces at the industry/regulatory interface including industry task force inputs to the US HPV Challenge Program, the OECD SIDS Programme and other chemical regulatory frameworks at both global and national level.

Mr John Yates, REACH Projects Manager, Caleb Management Services Ltd

John leads the delivery of a series of consortia that will focus on the assessment of chemicals data/data-gaps, the filling of these data gaps and subsequent submission of dossiers that meet the requirements of REACH. John has substantial senior projects management experience in a variety of manufacturing environments.

|

OR

|

WORKSHOP C

Developing Chemical Safety Risk Assessments through Effective Testing Procedures

One of the fundamental objectives of REACH legislation lies in reducing, refining and replacing animal testing. REACH will promote the use of data from in-vitro testing, validated (Q)SARs and data from structurally related substances (read across) when conducting chemical risk assessments.

Estimated data generated by (Q)SARs may be used both as a substitute for experimental data, and as a supplement to experimental data in weight-of-evidence approaches. Clearly the interpretation of such data and the selection of appropriate ecotoxicological tests will play a key role in developing effective exposure assessments and appraising hazards to human and environmental health. Testing on vertebrate animals will be seen only as a last resort; after all other data has been assessed.

This half-day workshop will take you through the steps you need to conduct a scientifically robust but practical risk assessment to comply with REACH testing requirements. Through case studies, group work and scenario planning you will learn tools to help you reduce, refine and replace animal testing. You will:

- Understand which toxicological and ecotoxicological tests are most suitable for your needs

- Decide when and how to use alternative methods (in vitro, (Q)SARs) or animal testing

- Interpret, justify and report testing data

- Reduce costs through intelligent testing strategies

- Develop exposure and hazard scenarios

Workshop Leader

Arthur E Putt, Research Director, Springborn Smithers Laboratories

Arthur has extensive experience in the design of GLP-tests and their interpretation. Over the past 19 years, he has conducted and applied test results to environmental risk assessments. His main experience is in aquatic ecotoxicity testing.

|

13.00 – 15.00

|

LUNCH & DROP IN CLINIC

The opportunity is provided to discuss individual issues related to REACH on a one-to-one basis with any of the experienced workshop facilitators. 20 minute appointments can be booked through Smithers Rapra on a free, no obligation basis for those attending the workshops.

Early Registration Offers

Register before 16 July 2008 to take advantage of the special Early Bird Discount registration fee.

Companies sending one or two delegates

€850 + VAT at 21% per delegate before 16 July 2008

€1050 + VAT at 21% per delegate after 16 July 2008

Companies sending three or more delegates

€750 + VAT at 21% per delegate before 16 July 2008

€950 + VAT at 21% per delegate after 16 July 2008

Half day workshops (each)

€400 + VAT at 21% per delegate before 16 July 2008

€450 + VAT at 21% per delegate after 16 July 2008

Registration includes a copy of the proceedings, lunches and refreshments during the day.

Please send registration enquiries to Sharon Garrington, Conference Organiser. Tel: +44 (0) 1939 250283; Fax: +44 (0) 1939 252416

Conference Venue

The conference will be held at:

Park Plaza Astrid Antwerp

Koningin Astridplein 7

2018 Antwerpen

Belgium

Tel: +32 (0) 3 203 1234

Fax: +32 (0) 3 203 1251

With an economically strong hinterland and moderate year-round weather, Antwerp stands as one of Western Europe's most affluent cultural centres, thanks to its many museums and an affinity for music, fine cuisine, and pampered living.

Park Plaza Astrid Antwerp is centrally located in the heart of the world famous diamond area, opposite the monumental train station and zoo, near the bustling shopping areas 'De Keyserlei & Meir'. The hotel is also home of Aquatopia, Antwerp's newest and most exciting attraction with over 3,500 fish and other creatures. Other area attractions include the New Diamond Museum, the market and various museums. Antwerp Airport Deurne is a 10-minute drive and Brussels International Airport Zaventem is just a 35-minute drive.

Hotel Reservations

The conference will be held at the Park Plaza Astrid, Antwerp. Please use the Rapra Booking Form to book accommodation at the conference venue and send back to the number indicated on the form. (We do not handle accommodation from the Smithers Rapra office).

Nanopolymers 2008

Frankfurt, Germany, 7-8 October 2008

Addcon World 2008

Barcelona, Spain, 15-16 October 2008

TPE 2008

Prague, Czech Republic, 12-13 November 2008

RubberChem 2008

Prague, Czech Republic, 3-4 December 2008

Reach Houston 2009

Houston, USA, 19-20 January 2009

Polymer Electronics 2009

Barcelona, Spain, 4-5 February 2009

High Performance Fillers for Polymer Composites 2009

Barcelona, Spain, 4-5 March 2009

CALL FOR PAPERS

Smithers Rapra is pleased to announce the fourth 2-day international conference on High Performance Fillers for Polymer Composites to take place in Barcelona, Spain, from 4-5 March 2009.

Fillers have always played an important part in the development of polymer applications. The present scenario of rising energy, raw material and polymer prices, together with the emphasis on recycling and weight reduction, is creating opportunities and threats for existing products and opening the door to new ones.

The main theme of the conference will be how the fillers markets are responding to these challenges.

Why give a paper?

This is your chance to become part of an established event and to join what has traditionally been a prestigious panel of speakers at the forefront of filler technology. The conference will be attended by compounders, moulders, processors, materials specialists, polymer engineers and researchers in polymer science, together with end users of polymer materials. So if you have something to say, these are the people that need to hear it!

Presenting authors at High Performance Fillers 2009 will be entitled to a free registration on both days of the conference including meals, refreshments and a copy of the proceedings.

Papers are invited on:

- Market overviews and trends; including the effects of increasing polymer costs and of recycling issues

- Legislation affecting the industry

- Advances in filler production, particularly for reduced specific energy consumption

- Advances in the manufacture of filled composites, including reduction in energy costs.

- Developments in surface treatments

- Emerging fillers, especially those from recycled sources

- The use of fillers in all polymer types, including thermoplastics, thermosets and rubbers; film, fibre, sealants and adhesives

- The use of fillers with functional effects such as reinforcement, flame retardant, conductivity, magnetic, optical effects, rheology control, sound damping, density control and antiblock

- Papers on the production and use of the following filers are particularly sought. Carbon black, precipitated and fumed silica, precipitated calcium carbonate, non-continuous glass fibre, milled glass fibre and natural fibres.

REACH Antwerp 2009

Antwerp, Belgium, 21-23 April 2009

Leachables and Extractables for Pharmaceutical Products 2009

Barcelona, Spain, 12-14 May 2009

Blowing Agents & Foaming Processes 2009

Hamburg, Germany, 19-20 May 2009

In recent years soaring energy prices and a series of environmental regulations have hit the plastics industry hard. Materials costs are posing a significant economic challenge to manufacturers in high volume markets and, constrained by the market structure and strong competition for low-prices, many have been unable to transfer to their customers the increases in raw material expenses.

Pressure is on to find innovative ways to keep costs down, identifying new materials, sources and material alternatives. Foamed substrates may represent cost effective alternatives in many cases. Blowing agents or blowing gases are excellent “fillers” and have the dual benefits of saving material and reducing weight – the latter again minimizing shipping and other related expenses.

Today there are numerous solutions on offer – new methods, technology, processes, and additives – not to mention the wealth of experience in this area of plastics.

Smithers Rapra’s eleventh conference is now well established and the only one world wide offering such a range of academic, practical and industrial papers.

Drawing interests from all relevant industries involved in actual and potential foam applications, the next conference will be a good platform to report your findings and share experiences in various areas of expanded polymers such as:

- Standard, biodegradable and bio plastics

- Energy saving and foamed insulation

- Environmental view on foamed materials

- Environmentally safe gases e.g. nitrogen

- Foaming of packaging material

- Optimising cell structure through nano technology

- Latest discoveries, developments and fundamentals in foams and nanostructures

- Relation of foamed polymers and flame retardancy

- Processing: extrusion, injection moulding

- Studies on rheology of polymer/gas dispersed systems

- Using, introducing and controlling gases

Presenting authors at Blowing Agents and Foaming Processes 2009 will be entitled to free registration on both days of the conference including lunches, refreshments and a copy of the proceedings. If you are interested in presenting a paper at this event, please send a title, short summary, speaker name(s) and company name(s) to Alix Yates Fax +44(0)1939 252416 by the deadline of 7 November 2008.

Conference Language

Please note that the conference will be conducted in English.

Who Should Attend?

This conference is being developed for companies operating in the following sectors or manufacturing these products:

- Blowing agents

- PS foam board manufacturers

- PU foam manufacturers

- Resin suppliers for foam applications

- Gas companies

- Chemical blowing agent suppliers

- Foam injection moulders

- Foam extrusion companies

- Cable foam companies

- Wood-fibre composite foaming companies

- TPE foaming companies

- Foaming equipment manufacturing companies

- Mucell licensees

- Structural foaming companies

- Sound insulation

- Biofoaming

- Biodegradable polymer resin companies

Conference Venue

The conference will be held at:

Hamburg Marriott Hotel

ABC Strasse 52

Hamburg

20354

Germany

Phone: +49 40 3505 0

Hamburg, a charming European seaport and German commercial centre, is an ideal destination for business and leisure travel. Located in the city centre near the main train station, the Hamburg Marriott Hotel is ideally located.

Hotel Reservations

Please send reservation enquiries to Sharon Garrington, Conference Organiser, email conferences@rapra.net. An accommodation booking form will be sent with your joining instructions on receipt of your completed conference registration form.

Early Registration Offers

Register before 19 March 2009 to take advantage of the special Early Bird Discount registration fee.